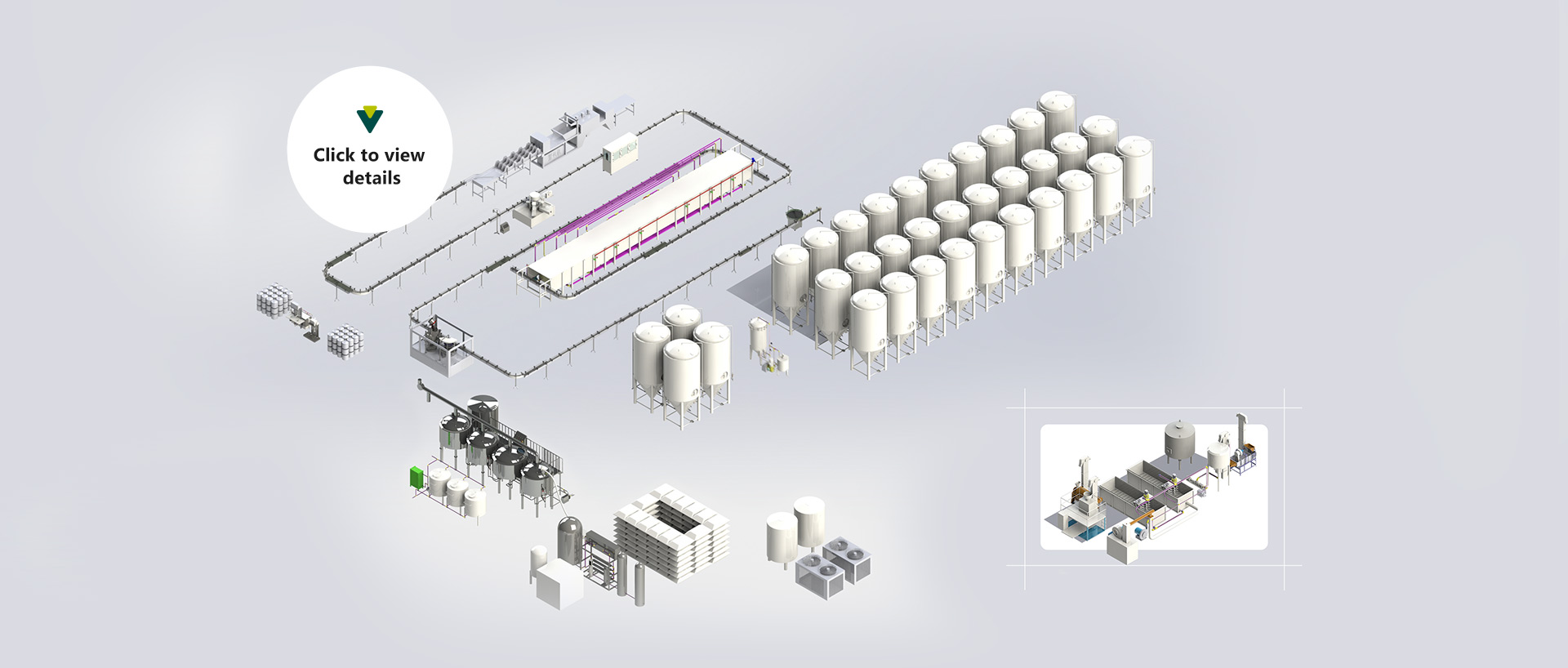

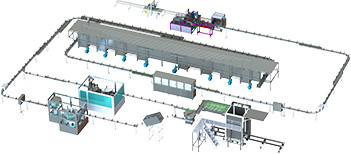

Beer complete line

Throughout our 23 years of partnership with the beer industry, we have developed a holistic understanding of everything that contributes to your performance. It materializes through unique value creation capabilities offering full complementarity: engineering services, line design, integration project management and equipment manufacturing which ensure top-notch cost optimization and environmental sustainability.

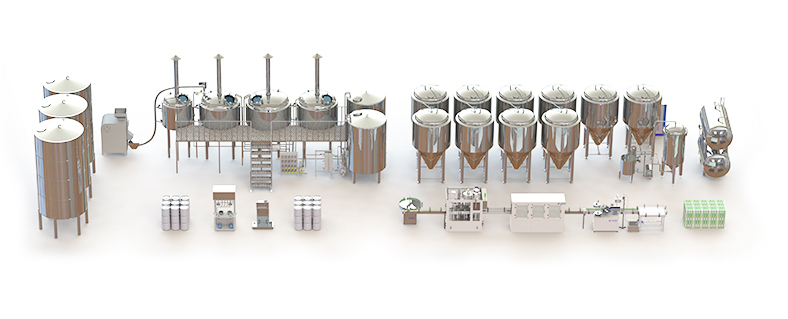

We provide a complete set of beer production equipment, including malting, mashing, fermentation, filling, sterilization, labeling, and packaging. With capacities ranging from 1000L to 200T, it can meet the needs of small commercial breweries as well as large industrial breweries. Our equipment is efficient and energy-saving, which makes your production process simple and controllable, can produce any type of beer, and help you quickly occupy the market.

Brewhouse

Simple industrial design intended to maximal effective work and high production capacity of the brewhouse

Fully piped and wired, including valves and sensors

CIP system: separated CIP for individual tanks to prevent cross product interference

Beautiful weld and polish: all argon gas protection welding. Polishing precision up to Ra0.6µm

World's top brands' electronic components: Siemens/Mitsubishi PLC and touch screen, Schneider button of circuit breaker, Airtac electromagnetic valves and other pneumatic parts, etc.

Controlling Unit: electrical controlling cabinet with temperature, on-off controlling for brewhouse; electrical controlling cabinet with temperature, on-off controlling for cooling parts; temperature controller, thermocouple, solenoid valves etc are included; PLC with touch screen panel for special request

✕

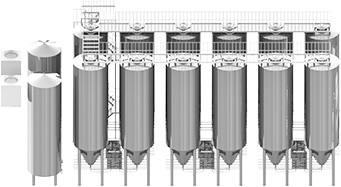

Fermentation Tank

By choosing and using various types of expansion accessories, it is possible to assemble the tank in several configurations that are optimal for the desired part of the production process

Standardized dimensions and equipment, or according to individual customer requirements

Accurate temperature control and reliable CIP are requirements to ensure a quality finished product

Cone angles can be changed to suit customer requirements

Guaranteed inner surface roughness : Ra < 0.8 μm or less (grinded surfaces) / Ra < 0.5 μm or less (polished surfaces), according to customer´s requirement

✕

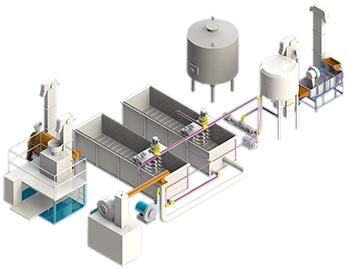

Filling machine

The combination of high quality robust machine construction along with close attention to the needs of clean in place CIP ensures our beer fillers deliver efficient reliable bottling production

Fast filling speed, high precision in liquid level.

Include double pre evacuation as a standard feature to ensure ultra low dissolved oxygen DO’s are maintained during the filling operation

Compact conformation, Easy installation,use & maintenance

High filling speed and mass flow rate, high precision of filling valve and control of liquids level is accurate and without loss

✕